VATROSTALNA DOO SKOPJE

REFERENCE LIST

VATROSTALNA LLC Skopje, as qualified and professional organization is an active participant in all overhauling activities in TPP BITOLA, TEC OSLOMEJ, FENI INDUSTRIES, SMELTER VELES, JUGOHROM, EVROPA, ALKALOID, Okta Refinery – Skopje, Cement Plant Titan-Skopje and other companies...

Duna Dráva Cement Kft – Vác in Hungary

- Disassembling and building in refractory material within the project for modernization.

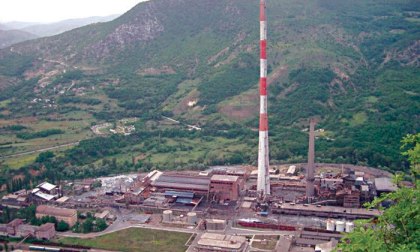

FENI INDUSTRIES, Kavadarci

- Complete lining of the facilities in a phase of investments, (EF, rotory kiln, converter, laddles)

- Current maintenance in exploiting phase

- Acid resistant protection

- Fire protection

TPP Bitola

- Refractory lining on all blocks (3) in investment and on-going maintenance of the same

- Acid proof works and anti-corrosive protection

- Performance of hydro insulation with hydrofoil on Block 1 and Block 2

ALKALOID Skopje

- Performance of floors and their acid resistant protection

- Refractoryworks on steam boilers

- Performance of hydro insulation on the office facility (with no application of coating)

- Performance of hydro insulation on facilities in the plant, flxible location Lafoma

OKTA Refinery

- Torquetting and lining of furnaces

TITAN Cement Factory

- Lining of rotary kiln

EVROPA Skopje

- Performance of floors and their acid resistant protection:Acid Resistant tiles, Acid Resistant coatings on base of epoxydes, polyurethane and polyester)

- Refractory works on steam boilers

TOPLIFIKACIJA Skopje

- Refractory works on steam boilers

- Gas stacks repairs

FERRONIKELI GLOGOVAC, Kosovo

- Investment construction, general overhauls (electrical and rotary kilns) and complete refractory maintenance of all facilities from aspect of refractories, including selection since the beginning of the operation of the factory

RTB BOR

- Complete lining of the facilities in a phase of investments

- Acid proof works

- Construction of facilities for production of acid and tanks for storing in Drying tower, Inter-pass Tower, Final Tower, Dryer’s reservoir and reservoir of the End Tower

TREPCHA K.MITROVICA, Kosovo

- Refractory works in all facilities of TREPCHA (while producing Pb and Zn)

- Acid resistant works in all facilities of TREPCHA

- Reconstruction of the baths for electrolysis and insertion of BEKAPLAST tiles

- Sandblasting and rubber layering of certain facilities

- Repairs of different facilties

- • Performance of hydroinsulation of most production facilities in area of 5500 m2 (works are performed with PVC foil and the remainig with coatings) in the period from 1992 to 1998

TPP OBILIC

- Refractory works on all blocks including also the delivery of materials

- • Acid reisitant and anti corrosion protection

GERMANY

- Performance of acid resistant works in several termo power plants in Germany through the company KERAMCHEMI I STEULER

- Performance of acid resistant works through the company VESTERVAL

- Performance of works through German companies in third countries

REK Kichevo

- Refractory lining and on-going maintenance of the facilities

- Acid resistant protection: Installation of acid resistant tiles, in major number of aggregates

- Sand blasting and rubber layering of certain aggregates

- Monolythic acid resistant coatings

- Performance of hydro and thermo insulation

- Overhaul and sanation of gas stacks